Incidence core

Home /

Collapsible cores for the plastics industry

The market demands ever more complex plastic parts at lower prices. The collapsible core is the ideal solution for demoulding injection-moulded parts with threads, undercuts or claws as cost-effectively as possible. Undercuts of 12% can be demolded without any problems – in special cases, 17% to 20% undercuts are possible with a 2-stage system (product innovation).

Each drop-in core is manufactured specifically to your customer requirements. The most diverse contours can be realized. Diameters from 8 mm to 240 mm are possible, with a contour length of up to 130 mm. The overall length of the drop-in core is determined individually.

We deliver the collapsible core with the complete contour to you ready for installation – so that your complex plastic part can meet the high quality requirements at low prices.

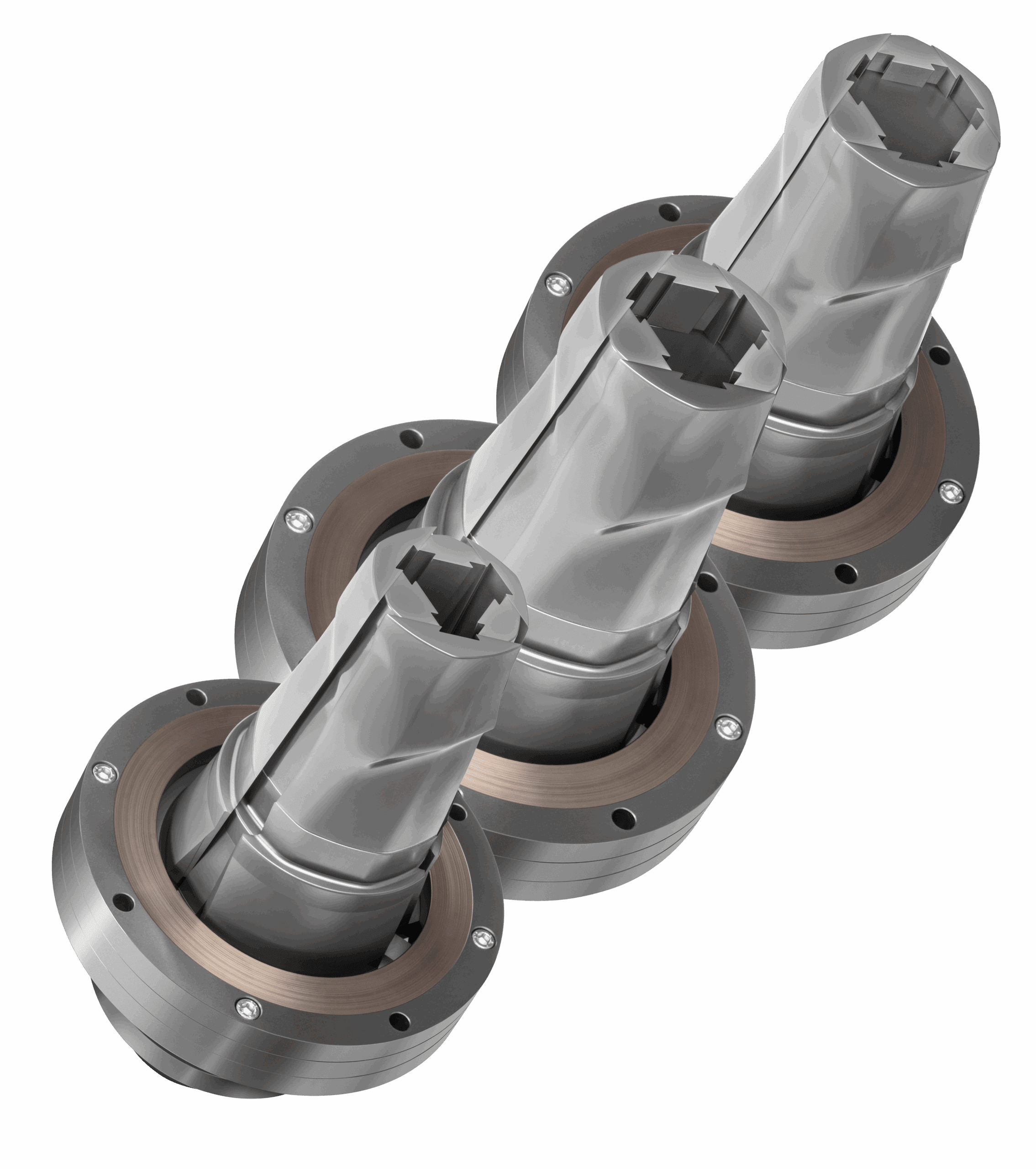

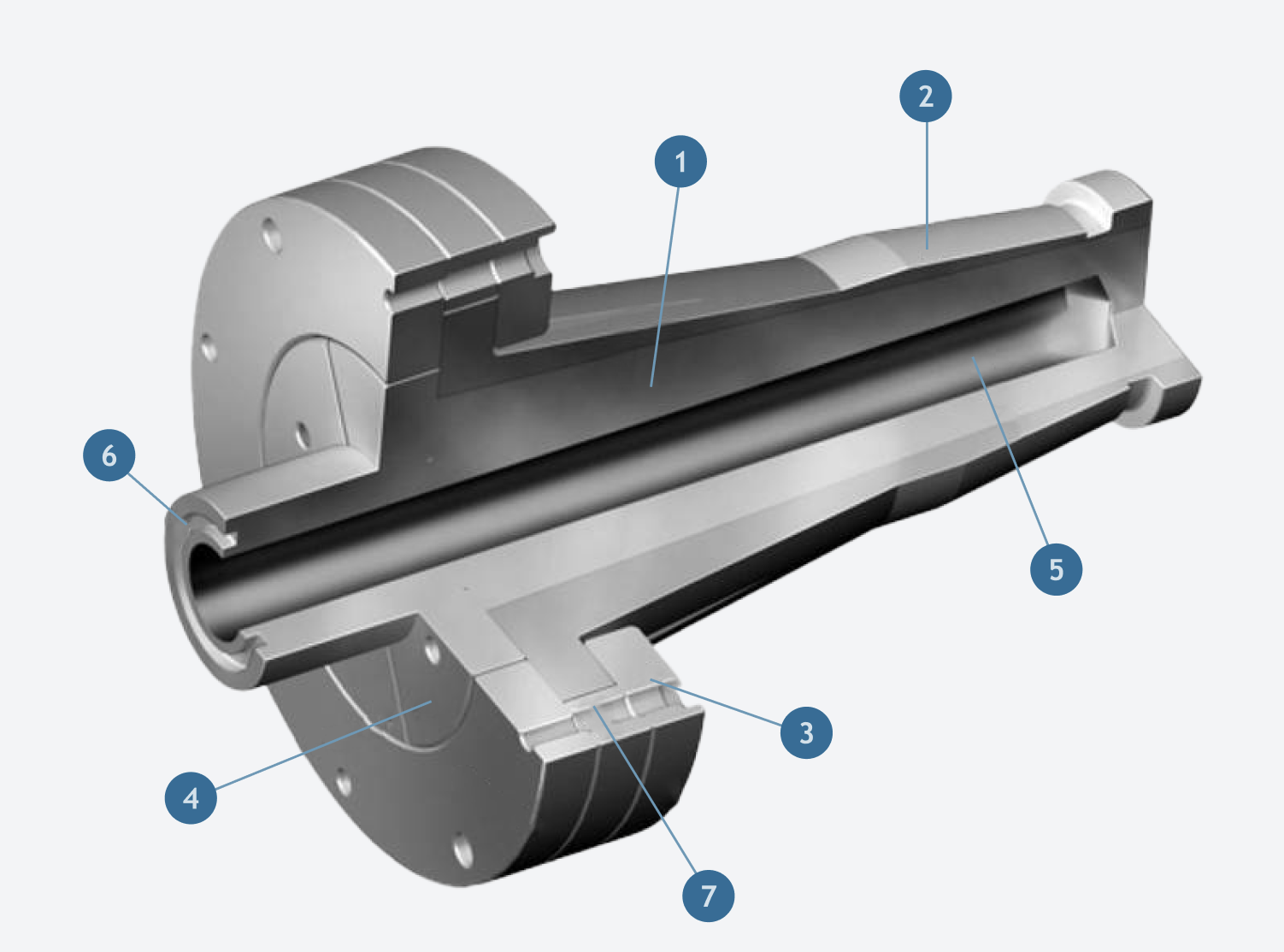

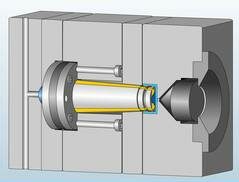

This is how collapsible cores are constructed

The structure

The collapsible core consists of several precisely coordinated components – here you can see the structure in detail.

- Center core

- Outer segments

- Retaining plate

- 2 half rings

- Cooling bore

- Sealing groove for O-ring

- Spacer ring

Processing of collapsible cores

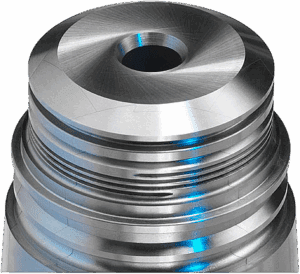

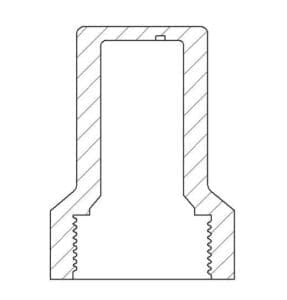

Contour processing

Thread contour on the collapsible core

The collapsible core is suitable for a wide variety of undercuts. Thread contours can be easily demolded with your collapsible core.

Profile contour at the collapsible core

A wide variety of profile contours are possible on the collapsible core so that your special plastic part can be demolded quickly and easily.

Special finishes Reduce nest spacing

Special machining – specifically for your requirements

Minimize nest spacing for multiple forms:

- Flatten movement rings

- By installing the collapsible cores in hard panels, the movement rings are completely eliminated

Special finishes Reduce nest spacing

Contour combinations Grinding, milling, die sinking

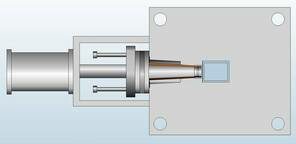

How collapsible cores work

Function

Normal demolding

Normal demolding via open and close movement. Stripping takes place with a stripper plate, which is actuated via a latch pull or 2-step ejector.

Side demolding

Demolding of the undercut or thread in the parting line using hydraulic cylinders. Multiple demolding is also possible with one cylinder.

Cap demolding

For undercuts on the face side or long contours, the use of a moving cap is necessary. This cap is guided through the collapsible core. The cooling option is located in the guide rod of the cap.

This is their benefit through the use of

Your advantages

The collapsible core offers clear advantages for all those involved – from design and production to costing. With its well thought-out structure, simple handling and noticeable increase in efficiency, it ensures smooth processes and economic added value.

Quick and easy construction

Round cut-outs enable compact shapes & quick implementation.

Assembly without effort

Supplied ready to install – no spindle mechanism, no additional parts.

Efficient injection molding process

Smaller tools, shorter cycles and easy handling.

Economically convincing

Less effort, lower costs – the core pays off.

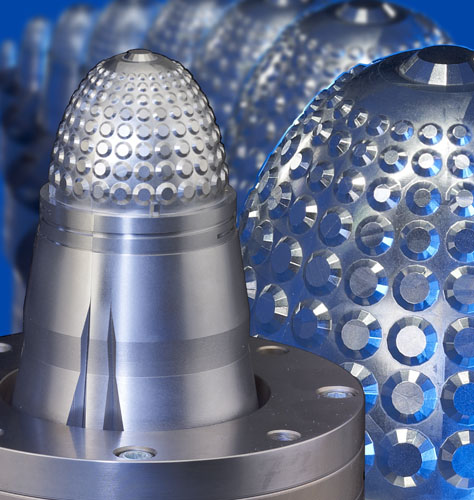

Here are pictures of our incidence cores

Examples of our collapsible cores